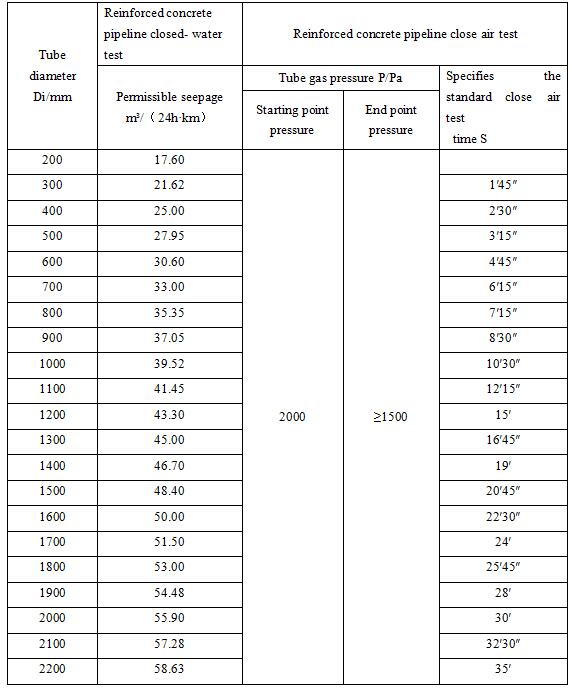

1.Reinforced concrete pipeline close air test standard

Permissible seepage calculation formula:q=1.25√D

Reinforced concrete pipeline close air test standard See Table 1

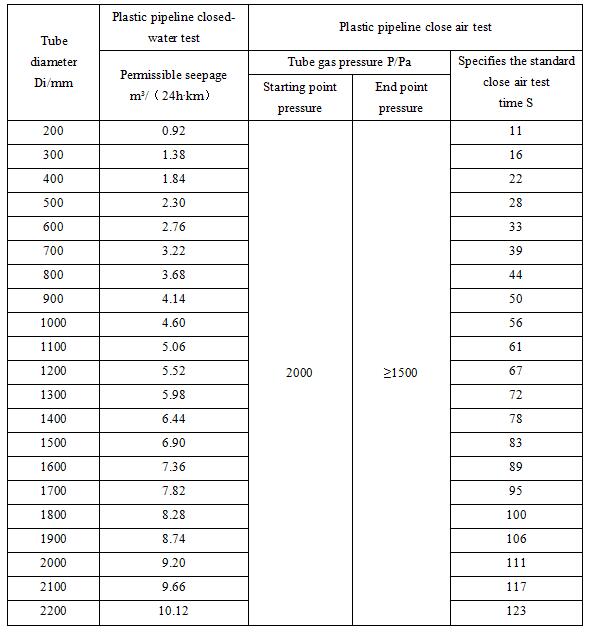

2.Plastic pipeline close air test standard

In recent years for the municipal engineering in the plastic drainage pipe is mainly high-density polyethylene(HDPE) double wall corrugated pipe, hard polyvinyl chloride (PVC-U) double wall corrugated pipe and steel belt reinforced polyethylene (PE) spiral bellows,Its unique wall structure makes the pipe with ring stiffness,strong compressive strength, light weight, low drainage resistance,high pressure resistance, good toughness,corrosion resistance,good sealing interface,good bending performance, adapt to the uneven settlement of the foundation,low installation cost, simple construction, shorten the construction period, long service life (Buried for more than 50 years) and so on,can be widely used in municipal drainage constuctions.

DB 29.155-2006 Plastic Drainage Pipeline Engineering Close Air Test standards and expansion (Added D1300 mm-D2200 mm ten kinds specifications of the standard test parameters), is based on the China Engineering Construction Standardization Association Standard CECS 164: 2004 Technical Code for Buried Polyethylene Drain Pipeline (It is suggested that the Close Air Test can be used in pipeline air tightness test ) and CECS 122:2001 Permissible Permeability of Buried Polyvinyl Chloride Drainage Pipeline Engineering Technical Specifications (The relevant standards are According to the third edition of the Strictest USA< PVC pipeline design and construction manual> in 1991 ),after kinds of tests then be written.

Permissible seepage calculation formula:q=0.0046D

Reinforced concrete pipe close air standard See Table 2

Table 1 Reinforced concrete pipeline close air test standard

Table 2 Plastic pipeline close air test standard

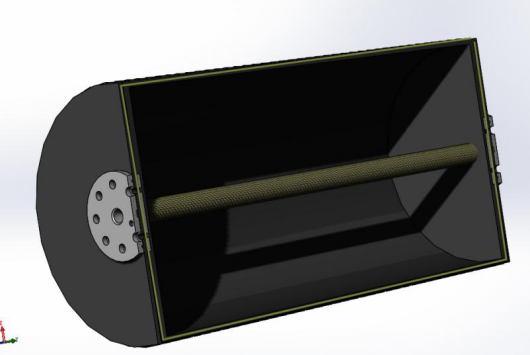

3.Plug

1)Normal Plug

Suitable for Chinese pipeline plug size:

DACHENG 8″~12″ : 200 mm~300 mm

DACHENG 10″~12″: 250 mm~300mm

DACHENG 12″~14″: 300mm~350mm

DACHENG 15″~24″:380mm~600mm

DACHENG 24″~31″:580mm~800mm

DACHENG 31″~48″:780mm~1250mm

4.Close Air Test Bypass Inflatable Pipe Plug

Material: rubber with canvas layers

Parts: hose inside of the plug for air insert the pipe flange , quick union and rings

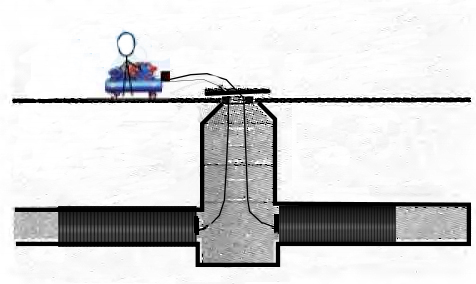

Bypass Inflatable Pipe plug air testing

The closed-water test of the non-pressurized pipe requires a well test, and the airtight test does not mention the well Test, USA have the well closed gas test standards,

Closed water test for non-pressurized pipelines

It is recommended to check the allowable seepage of the well according to GB 50268-2008 9.5.3 shaped cross-sectio of the allowable seepage of the pipeline can be converted into a circular pipe circumference calculation.

5.Pipeline deformation test

CECS 164: 2004 Technical Specifications9.2.1 for Buried Polyethylene Drain Pipelines,When backfill to the design elevatio,measure the initial deformation of the vertical diameter of the pipeline within12h-24h,and also calculate the initial deformation rate of the vertical diameter of the pipeline.The value shall not exceed 2/3 of the allowable deformation of the diameter,and allowable diameter deformation rate requirements need be less than 5%,When the deformation exceeds 5%, the interface between the pipelines and the interface between the pipeline and the manhole may be seeped, resulting in the loss of backfill sand, and even affect the safety of the roadbed,and appear collapse phenomenon.The pipeline effectively support angle range and the backfill quality on both sides of the pipeline are very important,that make the pipeline top forms the soil arch so this must be given sufficient attention, The pictuire 6 is the pipeline with Serious deformation.

Pipeline with Serious deformation

The deformation of the pipeline can be tested by means of a circular mandrel or a closed circuit television. The measurement deviation shall not be greater than 1 mm, When the initial deformation rate of the vertical diameter of the pipe is greater than 2/3 of the allowable deformation rate of the pipe diameter and the pipeline itself is not damaged, the following procedure can be corrected until the requirements are met:1)Dug the groove backfill soil till exposing 85% of the pipeline height, the top of the tube above 0.5mm must be Using artificial mining,2)Check the pipeline, when there is damage, can be repaired or replaced.3)Use the backfill material which can achieve the required density, and re-filled with the required density,4)Re-measure the initial deformation rate of the vertical pipeline diameter

References:

[1] GB 50268-2008, Water supply and sewer pipeline construction and acceptance of norms [S].

[2] CECS 164: 2004, Buried polyethylene pipeline technical specifications [S].

[3] DB 29-155-2006, Plastic drainage pipeline project suspend breathing test standards [s]

[4] CECS 19:90,Reinforced concrete pipeline suspend breathing test standards[s]