1.Design requirements

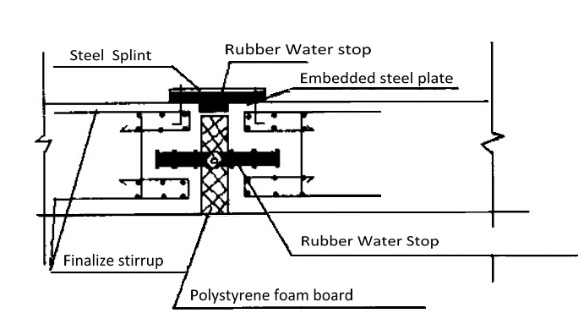

The rubber water stop is divided into detachable type and embedded type according to the installation method.The detachable type Which is using splints to install at the embedded bolts. The embedded type which is putting the rubber water stop partially or entirely poured into concrete during the concrete pouring process (see Picture 1)

2.Material requirements

2.1 Order planning

Before putting forward the purchase plan to the manufacturers, First Calculate the detailed dimensions and draw the detailed three-dimensional space figure . Design the length modulus of the rubber water stop to make the joint position in its flat parts, be away from the structural angle or intersection keeping 60cm or more ,and set aside the amount of lap .if special plane or spatial intersecting node,please contact the factory to customized stereotypes rubber water stop node.

2.2 Approach test

In addition to make sure model, size, quantity,and product certification of the rubber water stop in sence,also should sample review, observe and acceptance.The surface of the rubber water stop shall not be cracking, glue lacking, stratification and other damage phenomenon.The dents, bubbles, impurities, scars and other defects whose depth is not less than 2mm and area is not greater than 16mm shall not be more than 4 places.The deviation of rubber water stop size and the center hole should be within the allowable deviation.Focus on checking the middle of the rubber water stop ring, if necessary, after human tensile then test.

2.3 On-Site placement

The rubber water stop is stored in the greenhouse for its special erection,under the overhead 20cm,At the same time in order to prevent sun exposure,It is forbidden to put together with organic solution or some solution can react with it.During the construction process, in order to ensure the exposed rubber water stop without damage,use ropes to wrap 1 layer of clean straw then cover onto the exposed surface.

And with a wooden stool to make the rubber stop belt overhead,The height of the wooden stool is according to the design elevation position of the water stop which is placed horizontally , and the distance is 2m.

2.4 Joint handling

In the rubber water stop joint, adopt 20cm heat connection method.In accordance with product performance it should be on-site processing by the factory professionals,After the heat connection, should be exterior inspection for each joint.

2.5 Semi-finished product protection

During construction,should pay attention to protect the semi-finished product In particular.For example:Try to stay away from rubber water stop while welding operation;The water stop near the solder joint must be masked with a board while

embedded steel plate installation.When carry steel bars nearby, pay a special attention to prevent rubber water stop from collision.

3. Installation and fixation

The key of the installation work is to make the ring of the rubber water stop fixed in the deformation joint center.

3.1 The Installation and fixation of embedded type rubber water stop

3.1.1 Die fixed rubber water stop

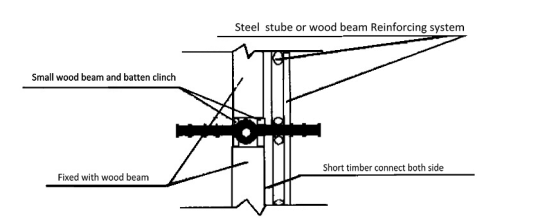

Before the mold, the measurement should mark the positioning ink line first in the cushion to determine the location of the deformation joints.Keep the positioning ink line exposed outside in order to check the deviation of the rubber water stop,After the steel bars were tied, install and fix the rubber water stop as the picture 2 shows.

Which does not use the plate to set the level of the rubber water stop , these can use stereotypes steel hoop to ensure its accurate location.The opening parts of the steel hoop should about 50 mm high,The end of the rubber water stop should be about 50mm higher than the center of the ring to make the horizontal set of rubber water stop can discharge air during artificial vibrating operations,For the parts of no plate fixed of the vertical set of rubber water stop,every 300 mm pitch,use the concrete pad to fix in the stereotypes steel hoop.

Use two block (size 50mm * 50mm) of reinforced woods on both sides of the rubber water stop , the rest part use the steel mold according to the thickness of concrete. Use one short wooden to connect two sides,and the space is 1m,Make sure both sides of the wooden have connected into one to hold the rubber water stop, Between the steel pipeline support system outside and the plate use the fasteners and 8 lead wire to fix together.

In order to control the center height of the horizontal rubber water stop, mark elevation control line on the plate and weld a steel bar with water stop ring to control the inspection elevation at the bottom of the steel bars,the space is 1m.The verticality of vertical rubber water stop should be used the way of hanging line which means to control line position from the bottom to control it.

After the design strength has achieved more than 30%,the deformation of the side of the concrete can be demolished, and then pour the other side of the concrete.

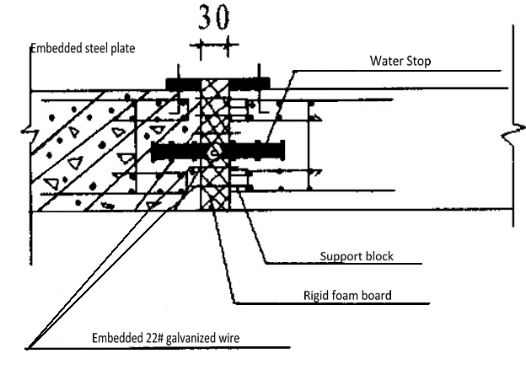

3.1.2 The fixation of polystyrene foam board

Place the polystyrene foam board on the side of the formed concrete and tie the foam board to the concrete with the embedded No. 22 galvanized iron wire,And then on the stereotypes steel hoop at the side of the concrete which not pouring,withstand the foam board at the concrete pad whose thickness is the protective layer of the thickness.(see picture 3)

3.1.3 Concrete construction

Check the location and the structure of the rubber water stop if they are consistent with the design requirements or not;if the joint position processing is correct or not; if there are dust-free, debris on the rubber water stop or not, and also make sure the water stop has broken and cracked phenomenon or not . After confirmation,that can be poured concrete.

When pouring the concrete into the horizontal setting deformation seaml,firse reinforce the concrete near the rubber water stop , and then use the water-type vibrator bar to tamping the concrete below the rubber water stop,until poured about 5cm high away from the bottom of the rubber water stop,re-load the concrete,hold the end of the rubber water stop with a blunt hook,

use a round stick to tamp the rubber water stop step by step,so that can facilitate the exhaust and concrete dense.Due to the use of slump larger pumping concrete,so the requirement of the end of rubber water stop should be 40 ~ 60mm higher than the design position,It is advisable to use a small vibrating bar to control the insertion depth,and do not hit the rubber water stop.

For the vertical rubber water stop ,should be poured on both sides at the same time.At the time of pouring, the concrete should be transported to the vicinity of the deformation joints, artificial cutting, and pay attention to the shovel can not hit the rubber water stop or plate.

3.2 The installation and fixation of removable rubber water stop

3.2.1 The construction of embedded bolts

The embedded bolts must be fixed to the steel plate in advance and then poured into the concrete.The below of the embedded steel plate with steel plate water stop should be carefully vibrated.In order to make the removable rubber water stop easy to installation,the corners of

variant seam should be make arc or 45 angle,The radius of the arc should be determined according to the length of the embedded bolt,The distance between the two adjacent bolt heads does not affect the installation of the water stop and the water stop plate,generally 250 ~ 300mm is appropriate.The embedded steel plates and plywood should also be the same shape,When embedding the bolts, first should spread butter on the bolts to protect the PVC pipeline.

3.2.2 The fixation of rubber water stop

According to the actual location of the bolt,at the site we should use the belt punch to fixed rubber water stop so that can ensure the accuracy of its location.Install from the beginning of complex nodes, and then to both sides of the installation.During construction, the first

put the rubber water stop along the embedded bolts,And then punch the hole according to the location of the bolt.After punching a suitable distance ,install the rubber water stop on the embedded bolts to prevent temperature deformation from affecting position accuracy.Throughout the installation process,do not be hard to pull the rubber water stop.Between the rubber water stop and the clamping plate and the embedded steel plate all should use slate board paperboard or soft sheet metal liner to keep it tightly.

4 Effectiveness analysis

By taking a series of measures as above mentioned,the horizontal offset, vertical, elevation, deformation axis displacement of the rubber water stop are controlled within the allowable deviation, the installation quality also meet the standard requirements,In winter when some large pools shrinkage 1.5cm, or the groundwater level rises above the surface of the pool floor for 5 meters ,we don’t find there are some leakage phenomenon at the deformed seam.there are some specific construction examples:Hayi gas project sewage pool and sewage pumping station project in 1992, Harbin Wilson Square Project in 1997,Inner Mongolia Tuoketuo Power Plant Wang Yuying Railway Station, Lanjiayao Railway Station Water Storage Project in 2003,Harbin Medical University Gymnasium Project Swimming Pool Project in 2006,These projects are in accordance with the above methods of construction, all have reached the quality requirements.