Neoprene bridge bearings - plain or laminated - elastomeric bearings are much easier to install in a bridge than compared to other types of bearing used and require nil maintenance. Unlike most other elastomer, Neoprene rubber under-goes no marked stiffening at low temperature when the thermal contraction of the bridge deck is at maximum. Such stiffening could be deleterious to bearing and / or structure. Correctly-designed and suitably-compounded laminated Neoprene Rubber bridge bearings can be confidently expected to function efficiently for at least a decade.

Advantages of Neoprene Elastomeric bearings.

As efficient bearing plates for pre-cast, pre-stressed concrete or steel beams in bridges and buildings, Neoprene Pads - plain and laminated - manufactured by us permits a smooth and uniform transfer of load from the beam to the substructure and allow beam rotation at the bearing due to deflect ion of the beam under load. They further allow lateral and longitudinal movement of the beam caused by thermal forces. Neoprene Pads have no movable parts and thermal expansion and contraction are absorbed by the pad's ability to give and take in shear. There is no sliding motion between pad and beam or between pad and abutment.

Neoprene bridge bearing specifications.

The material specifications for the elastomeric bearing shall meet all the current requirements of AASHTOM M 251. Construction, of the AASHTO Standard Specifications for Highway Bridges.

Bearing pads and laminated bearings shall be of the compound known as neoprene and shall be cast in molds under pressure and heat. A plain elastomeric bearing pad and steel load distribution plate combination shall be classified as a laminated elastomeric bearing. Test specimens shall be in accordance with ASTM D 3182 or D 3183. Where test specimens are cut from the finished product, a 20 percent variation from the original physical properties is allowed.

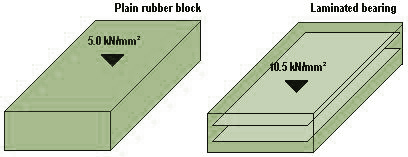

Difference between a plain rubber block and laminated elastomeric bearings

The capability of plain rubber block to carry vertical load increases as the number of laminations..mild steel shims increases.

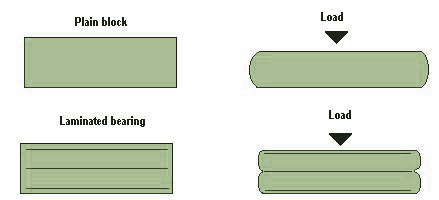

How a plain rubber block and laminated bearing reacts against vertical load.

Plain rubber block under vertical load compressed down where as a laminated bearing bulge out with each laminations absorbing most of the vertical load.

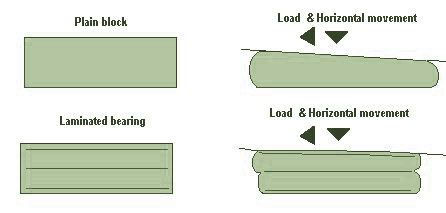

How a plain rubber block and laminated bearing reacts against horizontal load.