elastomeric bearing pads

elastomeric bearing pads

Dacheng Elastomeric Bearing Assemblies are custom molded using neoprene or natural rubber and are categorized into three basic designs : laminated elastomeric bearing pads, PTFE sliding bearing pads and plain elastomeric bearing pads.

Dacheng Elastomeric Bearing Assemblies are custom molded using neoprene or natural rubber and are categorized into three basic designs : laminated elastomeric bearing pads, PTFE sliding bearing pads and plain elastomeric bearing pads.

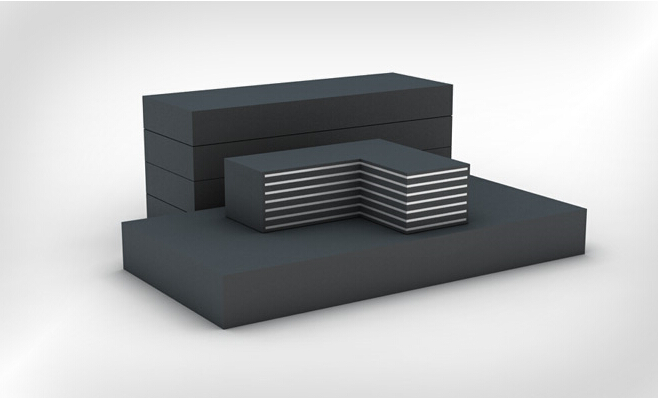

- Laminated Elastomeric Bearing Pads

Dacheng elastomeric laminated bearing pads with simple reinforcement are made up of multiple elastomer layers separated by reinforcing steel plates, sulfurized and moulded together can be manufactured in a rectangular or circular shape to meet individual engineering requirements. General laminated bearings suits to bridges with span less than 30m and small displacement.Different flat shape suits to different bridge span structures : orthogonal bridges adopt rectangular bearing; curvilinear bridges, oblique crossing bridges and cylindrical pier bridges adopt circular bearing.

Dacheng elastomeric laminated bearing pads with simple reinforcement are made up of multiple elastomer layers separated by reinforcing steel plates, sulfurized and moulded together can be manufactured in a rectangular or circular shape to meet individual engineering requirements. General laminated bearings suits to bridges with span less than 30m and small displacement.Different flat shape suits to different bridge span structures : orthogonal bridges adopt rectangular bearing; curvilinear bridges, oblique crossing bridges and cylindrical pier bridges adopt circular bearing.

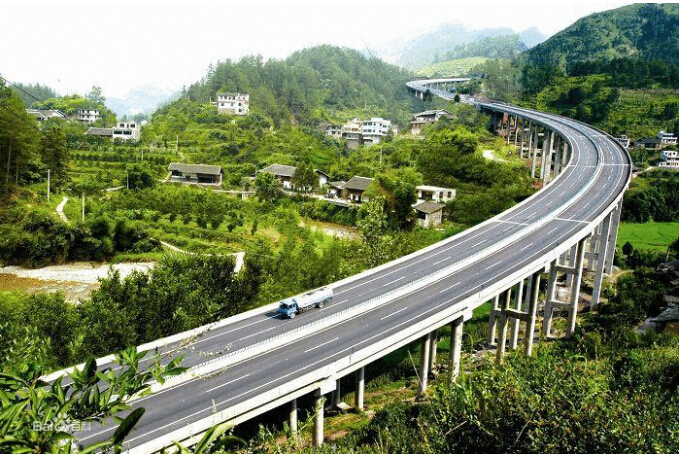

Applications:

Elastomeric Bearings have been designed to be very easy to install, maintenance-free and cost-effective. The product has been successfully used in a broad range of applications which include : bridges, viaducts, high rise buildings, stadiums and dams.

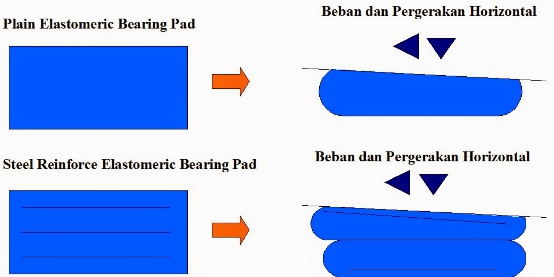

Elastomeric Bearings are designed to accommodate three types of movement : Vertical , Shear , Rotation. To transfer the load from the superstructure (both vertical and horizontal) to the substructure. Bridge with span less than 10m don't normally require any bearings. To accomodate translational movements(expansion and contraction) e.g. movement due to temperature (can be large in steel bridges, up to 300mm); due to dead load & live load especially sloping road; shrinkage and creep etc.To accommodate rotational movements of deck girders. Rotation occurs as the deck deflect under load. Also, some relative rotations occur in composite section due to different properties of concrete and steel. Differential settlement may also cause some rotational movement. To limit forces transmitted to the substructures by suitable design.

Elastomeric Bearings are designed to accommodate three types of movement : Vertical , Shear , Rotation. To transfer the load from the superstructure (both vertical and horizontal) to the substructure. Bridge with span less than 10m don't normally require any bearings. To accomodate translational movements(expansion and contraction) e.g. movement due to temperature (can be large in steel bridges, up to 300mm); due to dead load & live load especially sloping road; shrinkage and creep etc.To accommodate rotational movements of deck girders. Rotation occurs as the deck deflect under load. Also, some relative rotations occur in composite section due to different properties of concrete and steel. Differential settlement may also cause some rotational movement. To limit forces transmitted to the substructures by suitable design.

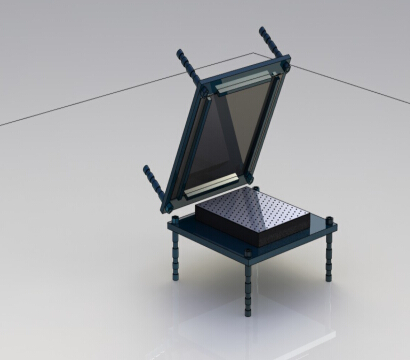

- PTFE Sliding Elastomeric Bearing pads

Laminated elastomeric bearings with PTFE sheet bonded on the elastomer:a virgin PTFE layer is bonded to the elastomer to reduce the friction coefficient with the stainless steel welded to the top steel plate. Tetrafluoro plate type rubber bearing suits to bridges with large span,several spans in continuous, with simply supported beam and continuous plates structure, and large displacement.It can still used as the sliding block in purchasing of continuours beam and cross sliding of T-shape beam.

The application of rectangular and circular tetrafluoro plate type rubber bearings are the same with rectangular and circular general plate type rubber bearing, separately.

- Plain Elastomeric Bearing Pads

Plain Elastomeric Bearing Pads can be used in many construction and civil engineering applications to support concrete and steel structures, and where a simple, low-cost rubber separation strip is capable of carrying compressive loads, while at the same time providing translational movement and rotational capacity. Plain pad bearings have a large and varied range of possible applications though these bearings are more typically used in prefabricated structures. Materials : EPDM, natural rubber or neoprene.

Plain Elastomeric Bearing Pads can be used in many construction and civil engineering applications to support concrete and steel structures, and where a simple, low-cost rubber separation strip is capable of carrying compressive loads, while at the same time providing translational movement and rotational capacity. Plain pad bearings have a large and varied range of possible applications though these bearings are more typically used in prefabricated structures. Materials : EPDM, natural rubber or neoprene.

Design examples that illustrate some of the concepts discussed are included in this section.Summarizes the major design requirements used in these examples.

|

Non-reinforced Elastomeric Bearing Pad |

Laminated Elastomeric Bearing Pad |

PTFE Sliding Elastomeric Bearing Pad |

|

| Live Load | 110KN | 1200KN | 1200KN |

| Dead Load | 200KN | 2400KN | 2400KN |

|

Longitudinal Translation |

±6mm | ±100mm | ±200mm |

|

Rotation about Transverse Axis |

Negligible | 0.015radians |

0.05radians accommodated by elastomeric bearing |